Machine and Equipment Downtime Monitoring and Tracking through Interactive Reports and Dashboards.

Machine and Equipment Downtime Tracking – the Basics

Most downtime tracking applications involve monitoring a machine or piece of process equipment for conditions of shutdown. This downtime can be caused by many conditions, some expected and some unexpected. The goal of a downtime monitoring solution is to identify the reasons for downtime, categorize and analyze the reasons for downtime by quantity and duration. Armed with this knowledge, operators and plant management can drive continuous improvement to reduce their downtime and improve overall equipment effectiveness (OEE), where downtime is a major contributor.

Monitoring Machine and Process Equipment Downtime

Downtime Events are typically collected through direct communications with machines and process equipment. A condition, usually a digital signal, will signify the start of a downtime condition. The same signal or another signal will signify the end of a downtime condition. During the machine downtime tracking, variables will be collected and archived for subsequent reports and dashboards and further analysis.

However, downtime conditions can also be entered manually to create a database of events and data to analyze.

Typical Data Collected During a Downtime Event:

-

Start Time

-

End Time

-

Operator Name

-

Lot IDs or Product Serial Numbers

-

Machine Component IDs (Mold IDs, Tool Information)

-

Key Control Variables (Temperatures, Pressures, Cycle Counts, etc.)

-

Reason Codes for Downtime Reasons (automatically collected or manually entered)

These variables are collected in order to improve the machine utilization (reducing downtime), but also for quality purposes, so that product involved with downtime instances may be scrutinized or in the worst case, recalled in the future.

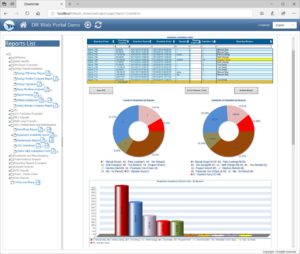

Calculations Performed for Downtime Monitoring

The most common calculations performed for downtime analysis are counts by downtime reason and accumulated downtime by reason. With an understanding of costs, these variables can be expressed in currency values (Dollars, Euros, etc.). These are commonly visualized with Pie Charts and Pareto Charts. Another common analysis to perform would be Downtime statistics by Operator or Downtime statistics by type of part – if one part has a higher instance of downtime due to design, hardness or another attribute. These analyses are performed over any period of interest and may also be automatically generated after a product batch or shift. Results are typically displayed in a browser based portal for management to see, and are displayed near machines, on big screen TVs to drive continuous improvement on the plant floor.

Dream Report is an Excellent Solution for most Downtime Tracking Applications.

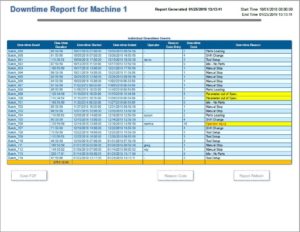

A special option for Dream Report, the DBATCH option, offers the ability to monitor real-time conditions and sense the start and stop of any condition. Often used for Batch Reporting, where reports and dashboards are automatically created based on a product manufacturing batches, the DBATCH option can also be used to monitor downtime conditions. DBATCH will uniquely NAME each downtime instance based o

n a user defined naming convention. DBATCH will store START and END date/time information as well as capture any number of variables that are valuable in this specific case of Downtime Reporting.

All information is stored in a relational database. The relational database of choice, virtually any ODBC compliant relational database, is identified by the user during system setup. Dream Report automatically creates a Database with associated Tables for data storage. This RDB repository becomes the source of Downtime Data along with any other data repositories that may already exist and be connected to Dream Report for other analysis purposes.

Pricing and Scalability to Meet ALL your Downtime Tracking and Other Needs, Cost Effectively

Machine and Equipment Downtime Tracking and Monitoring is a high value requirement that will easily justify a product purchase on its own. However, that purchase, typically costing tens of thousands of dollars, only does Downtime Monitoring. For Dream Report, Downtime Tracking is just another use and set of statistics that can easily be performed among its many other functions. Dream Report is the gift that keeps on giving, based on all the unique applications you can Dream up for it.

Learn more about Downtime from Wikipedia

Download the Dream Report Trial Version (Fully Functional) Today