Lifeway Foods, a public company (LWAY) based in Morton Grove, IL. USA is the maker of kefir and other probiotic foods for Healthy Eating™. Lifeway’s product lines are devoted to specialty dairy foods for health-conscious consumers, including probiotic cultured products and functional foods. Today, products are produced in one of four plants, three in Illinois and one in Wisconsin. These plants have varying levels of automation. Their most automated plant is based on GE Digital products – iFIX, Historian and IGS, with PLC5 and ControlLogix® controllers by Rockwell Automation.

Lifeway Foods, a public company (LWAY) based in Morton Grove, IL. USA is the maker of kefir and other probiotic foods for Healthy Eating™. Lifeway’s product lines are devoted to specialty dairy foods for health-conscious consumers, including probiotic cultured products and functional foods. Today, products are produced in one of four plants, three in Illinois and one in Wisconsin. These plants have varying levels of automation. Their most automated plant is based on GE Digital products – iFIX, Historian and IGS, with PLC5 and ControlLogix® controllers by Rockwell Automation.

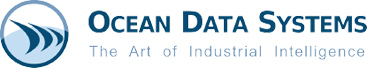

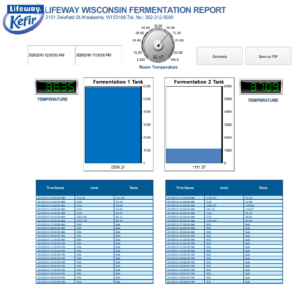

The making of kefir probiotic products involves the management of and growth of 12 live and active cultures and 15 to 20 billion beneficial probiotic strains. Cleanliness and managing sterility between batches is of utmost importance to ensure a quality product. The process of preparing equipment for the next batch is called “Clean in Place (CIP),” and the control system in place manages the automated operation of that process. But documentation of each CIP cycle is also important. Key parameters that are reported on are CIP ID., Operator Name and Return Temperature for each of the CIP portions of the process. A CIP typically takes from 1 to 4 hours depending on the complexity of the segment.

Documenting the CIP process was largely a manual process. While data was automatically collected and archived in a process historian, the documentation process involved utilizing historian client tools, primarily a Microsoft Excel add-in that will query the process historian for data and populate an area of their Excel workbook. Other steps included double checking calculations, tables and charts, printing a report and properly archiving all applicable files. While no single step is difficult, the combination of steps for all CIP operations becomes daunting and is a distraction from the primary Lifeway goal, making kefir with the highest quality and lowest cost possible.

We interviewed Zyril DeBorja, IT Manager for Lifeway Foods and asked about his whole experience, start to finish, with Dream Report.

We interviewed Zyril DeBorja, IT Manager for Lifeway Foods and asked about his whole experience, start to finish, with Dream Report.

Here are his answers.

What drove you make this change?

We are looking to automate as much as possible to best manage our quality and throughput. Our past manual process for reporting just wasn’t a valuable use of our time, and I knew there had to be a better way.

How did you find Dream Report?

I was researching Excel based automated reporting tools and came across the Dream Report website. The product immediately caught my attention as I could see it was designed for industrial applications. While reviewing the site, I also saw the many partnerships that Ocean Data Systems enjoys and that made me feel comfortable that it is a reasonable technology to evaluate. I specifically noticed that Dream Report has a GE endorsement and as our automation system, on the operator and information management side, is GE based, it seemed to make perfect sense.

Can you describe your experience in installing Dream Report?

Can you describe your experience in installing Dream Report?

I downloaded Dream Report and installed it on my computer. Dream Report installed without any issues. I started the product and it comes with a demonstration mode so I could evaluate it against my actual data. The demonstration mode runs for 30 minutes at a time and that was enough to get a feel for the capabilities of the product.

Once we were comfortable that the product would do what we wanted, we issued a purchase order and received a real license. Nothing had to be changed in our demo application. We just installed the new license and we were good to go.

Describe your experience in working with Dream Report.

When you first open the product, it can be a little overwhelming. There are lots of items to explore and some terminology to get up to speed with. I remembered that there were a lot of videos on the Dream Report website and I decided to check them out. That clarified a lot. After seeing the “Build a Report in 5 Minutes” video, I understood how to connect Dream Report to my data source and build a report. It really was that easy and you can actually connect to your data source and make a report that fast.

I was able to set up time based reporting without any trouble as that is the default for most items in Dream Report. Ideally, we would like to report on individual CIP processes and that required adding a feature to Dream Report called Digital Batch (DBatch). This option lets Dream Report monitor our control system and automatically store start and end times for our various CIP processes and automatically create names for them allowing us to quickly and easily recall a specific cycle. Dream Report can also generate reports at the end of each CIP, automatically.

What is your favorite feature of Dream Report?

What is your favorite feature of Dream Report?

I would have to say the Web Portal. I can walk up to any computer on our network and log into the portal to see past reports. I also created some interactive “Web” reports that let us browse any of our process historian data and make selections for date, time or batch (our CIP events) and Dream Report populates trends, tables and performs statistics on the data I selected. The Web Portal is interactive, so I can pan and zoom the trend data or search and sort the table data. Dream Report also has the ability to export data so I can use it in Excel if I want to. This is a great troubleshooting tool when we need to understand what is happening in our processes.

What’s Next?

We initially put Dream Report in to address our CIP reporting needs but we now see that we will be able to do a lot more with it. We have bottling lines, packaging lines and inventory that we will be reporting on in the future. Dream Report will not only free up my time, but it will also enable us to share information in the plant and that will lead to a better understanding of our processes, keeping everyone in the know, and keeping us focused on the right priorities.

In your experience, what’s the differentiator for Dream Report?

That’s an easy one. The ease of use of Dream Report is a really important aspect of the product. There is no programming or scripting. The product is configurable which means there are menus and selections to enable features and generate reports. While at the start I said the product could be a bit overwhelming, that was only because there is a lot to see when you first run it. Once you see a video and get used to poking around, it becomes very easy to use. I’ll be able to train others, our process people, to add or make changes to reports in the future. That would not be as easy in other tools that I’ve looked at, even the Excel based ones. Dream Report’s ability to run automatically also means I don’t have to schedule my time to use historian tools to retrieve and analyze data. Dream Report generates the reports I need and gives me an analysis interface that is very easy to use. A big part of my week is back for more important items.

We also use integrators for some work. I see that Dream Report would make their job a lot easier. They can stay focused on the content we need rather than getting all involved in programming and scripting, what most other products make you deal with. Dream Report is also a very complete product so there isn’t any technology that needs integrating. Many other products have option modules to email, a module to FTP, a module for a Web Portal, etc. Dream Report has that all built in.

Lastly, I would like to highlight the quality of Ocean Data Systems sales and support. They are very knowledgeable, attentive, patient and friendly. The kind of people you want to do business with.

Download a PDF of this Success Story