Preferred Utilities of Danbury, CT. is a leading source for expertise, products and services in the area boiler instrumentation and controls, high efficiency burners and fuel management systems across North America. Their markets include both small and large boilers, those typically found in hospitals, schools & universities, manufacturing facilities and emergency power systems. Founded in 1920, Preferred Manufacturing has had lots of time to hone their expertise. As a supplier of combustion controls, operator interfaces and data management systems, they’ve worked hard to deliver quality, reliability and a solution that delivers accountability. The delivery of performance information has always been a high priority for them.

Preferred Utilities of Danbury, CT. is a leading source for expertise, products and services in the area boiler instrumentation and controls, high efficiency burners and fuel management systems across North America. Their markets include both small and large boilers, those typically found in hospitals, schools & universities, manufacturing facilities and emergency power systems. Founded in 1920, Preferred Manufacturing has had lots of time to hone their expertise. As a supplier of combustion controls, operator interfaces and data management systems, they’ve worked hard to deliver quality, reliability and a solution that delivers accountability. The delivery of performance information has always been a high priority for them.

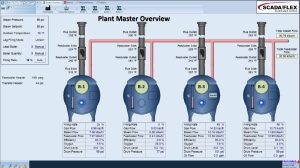

Their automation systems are a mix of both internally developed and third party combustion control systems, combined with an HMI/SCADA operator interface and data management system from various suppliers.

The operator interface is designed for real-time management of the systems. Communications with field equipment is typically based on MODBUS. This offers the operator the ability to read and write setpoints, tuning parameters and interact with the system to manage and optimize performance.

Preferred Utilities customers expect their systems to deliver the best performance possible and Preferred has delivered a variety of performance reporting solutions over their history. Early on, reporting solutions were based on custom software. More recently, report generation was based on an automated Microsoft Excel solution. Today, performance report generation is based on Dream Report. Many lessons were learned and this success story is intended to highlight some of the issues and concerns that plagued earlier solutions.

Custom Software – Every equipment OEM evaluates the tradeoff between creating and maintaining their own solution, potentially having a competitive advantage through a unique offering vs. leveraging third party tools that deliver the functionality they need. In early technology markets, the software tools you want may not exist or are too basic for the task. To an engineer, this looks like a development opportunity. Preferred developed and offered their own technology for reporting. While a good solution in the early days, a privately developed and custom solution doesn’t benefit from the feedback and varying customer demands that comes from a broad market solution.

Lesson 1 – While custom developed solutions may get the basic job done, they are ultimately quite limiting and costly to support in the long term. You are better off identifying and sticking to your core competencies.

Over time, third party tools with a focus on the automation industry became available. One common solution introduced in the 1990s was based on Microsoft Excel. The concept is to leverage Microsoft automation interfaces to insert data into an Excel workbook. Most Excel solutions leverage the math and print functions of Microsoft Excel. While making use of Excel as a calculation engine would seem a good fit for reporting, this approach can be problematic for the following reasons:

- This concept is not an “All in One” solution. The integration of multiple components from different vendors to craft a reporting solution will create a more fragile environment – reliability will be compromised. The solution may be easily and repetitively compromised by software or technology updates (Windows Service Packs)

- Excel based solutions may be impacted if Excel is used for other purposes on the same computer. Your visibility to the reliable background operation of Excel automation may be limited and you only know of failure when a report is lost, perhaps days after its intended generation.

While many users understand the fundamentals of Excel for business purposes, the use of Excel for automation related reporting presents challenges in the areas of missing data, bad data quality, rollover data and the required definition of a wide variety of vertical market statistics.

- Excel based reporting can create “Another Version of the Truth” as data is often replicated in Excel Workbooks for the purposes of reporting. These replicated files need to be managed long term and are difficult to recreate should reports need to be rerun at some point in time.

- Formatting and final results can be complex to create in Excel as pagination can be a challenge and graphic objects may not handle different data sets (varying sizes) elegantly.

- Distribution of the final results (FTP or Email) means the integration of additional utilities. This leads to lower reliability and a higher cost of ownership due to the management of a more complex installation.

- Security in any automation system is a core requirement. An integrated solution with Excel most likely does not offer a full featured security scheme and may not support Windows domain based security.

- Advanced interfaces for report management, manual data entry, mobile reporting, may not exist or if they do, they are additional modules that need to be managed in what is an even more complex solution. ActiveX controls are often a “feature” of these solutions and the support for browsers and mobile platforms may be very limited.

Preferred Utilities relied on Excel based report generation for several years and they experienced each of the limitations mentioned above. Over time, another solution emerged on the market, a solution purpose built for the world of industrial reporting delivering “All in One” functionality and leveraging all the latest technologies. That solution is Dream Report.

Lesson 2 – Have a look at new solutions that are on the market. You’ll be pleasantly surprised by the features and benefits that new technology and a “purpose built for industry” solution can offer.

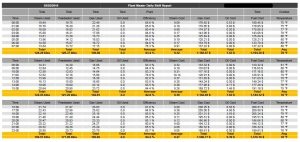

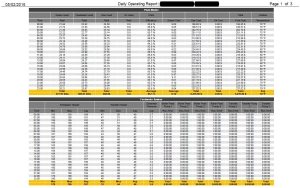

Today, with Dream Report, Preferred Utilities is offering one of the most advanced reporting and dashboard solutions on the market. Their reports are an ongoing validation to the quality and performance of Preferred Utilities combustion controls and fuel management systems.

Features delivered with the Dream Report solution include:

- Provide data/reports needed by some customers for environmental compliance.

- Reports are used to present information in human readable format and also to provide redundancy for the information retrieved from the equipment.

- Provide a measure of equipment for use in operations monitoring & maintenance purposes.

- Plant & individual boiler efficiency

- Energy consumption

Preferred Utilities heard about Dream Report from a distributor. Their first step was to review marketing materials and videos on the Ocean Data Systems Website. The second step was to arrange an overview Webinar with Ocean Data Systems, which took about an hour. Step three was the download of a trial package and the building of reports based on real customer data. Within a few days and some how-to support calls, Preferred Utilities had their first performance report, a template that will be used over and over in customer solutions. Dream Report offers a wide variety of features specifically developed for OEM use.

These include:

- Report Templates that allow for the creation of either standard formats for background and style as well as complete reports with pre-canned statistics and objects.

- Virtual Report Instances deliver the ability to elegantly handle repetitive environments such as those with multi-burner or multi-boiler installations. A report may be replicated for use, with the ability to tweak data sets to be used.

- Web Portal that allows branding and variable access based on user permissions.

- Project Deployment Tools enable Preferred Utilities to package new reports for end customers and deploy them easily at customer sites without needing system engineers.

When asked about his experience with the first Dream Report project, Paul Peterkin – systems engineer for Preferred Utilities stated:

“Every time I had a question about how to handle something in Dream Report, their support team was accessible and eager to help. I could build our first project, learning as I went along. Dream Report is certainly a very powerful tool and addresses our needs perfectly. We are very happy to be able to migrate from our earlier Excel based solution to a solution that is much more modern, flexible and addresses our market needs perfectly.”