Micro brewers are faced with many challenges, but if you’re Bear Republic, there’s another to add to the list – the availability of a key ingredient – water.

Bear Republic Brewing is located in Cloverdale, about an hour and a half north of San Francisco, and one of the hardest hit drought communities in California. In addition to working hard to make a great brew, they are challenged with a lack of water. Bear Republic is a significant brewing company having made the top 50 list of microbreweries in the USA. They have an annual production around 72,000 barrels.

As you can imagine, water makes up the majority of their product. In addition, a significant amount of water is required for the overall process, cleaning and the like. Industry averages highlight a ratio of 6 gallons of water use to one gallon of beer produced.

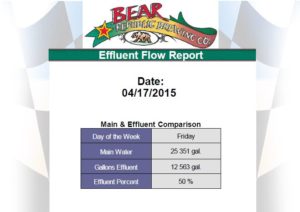

With city limits being applied to water use, it’s clear that Bear Republic needed to pay close attention to their water consumption. Close attention also included filing daily wastewater reports to the city of Cloverdale.

Bear Republic took significant steps to understand and reduce their water use. These steps included systems to recover water from waste streams, water that can be used in cleaning processes. These steps also included closely monitoring water use throughout the process, even from batch to batch, monitoring activities of operators to optimize water availability for brewing. Every gallon of water saved can be another gallon used to make more beer.

Current production is around 72,000 barrels a year. At 31 gallons per barrel and 3.5 gallons per gallon of beer, they are requiring 7.8 million gallons of water per year. The city has them capped at 8 million gallons annually. Clearly, water optimization is an important step in increasing production.

The process of monitoring and optimization required the installation of twenty-three water meters, a data acquisition system, historian and reporting / analysis software to generate and deliver the required results. Water meters feed their use data to a Siemens PLC. The Siemens PLC is monitored by a Wonderware Historian. The Wonderware Historian becomes the data repository for Dream Report, a solution by Ocean Data Systems and sold by our OEM (Wonderware). This combination of products delivers exactly what Bear Republic needed to meet the city reporting requirements and deliver the production analysis to make continuous process improvements.

Much of the Bear Republic solution was specified and initially configured by the Wonderware NorCal (Northern California) office. Dream Report is also delivered through this channel as a Wonderware branded solution. Mike Llapitan, Wonderware NorCal product specialist, provided the initial Historian and Dream Report installation and tag setup. The folks at Bear Republic quickly took the system over and had their first reports automated in a matter of minutes. They learned Dream Report on their own and no formal training was required.

A mandatory requirement of the system is to deliver a report of the previous day’s wastewater volume. Previously, this was a manual process and needed to be automated in order to keep the team focused on production and not busywork. With the flow data in Historian, Dream Report makes quick work out of daily totals and managing flow meter rollovers. Today, the water used and wastewater discharged report is generated automatically at 10:00am every morning. Dream Report scheduling can email and FTP that report to anyone that requires it.

Production needed to be streamlined to waste as little water as possible. Production also needed to be streamlined to optimize their equipment utilization and squeeze as much production out of their batching systems as possible. The ideal turn-around time from the emptying of one batch to the start of another should be 30 minutes. Reports can now track production by operator and if there are recognized areas for improvement, training is readily made available.

Dream Report offers a Web Portal that manages all reports for generation, access and review. Interactive reports enable management to drill into data to gain additional insights to production and plan for the future. Next steps will include monitoring the tank temperatures, batch to batch, to document and improve consistency, another step to brewing the best beer they can.

The challenge is not over. In November of 2014, Bear Republic announced that they will no longer be distributing to Massachusetts. Demand is high for their product and there just isn’t enough to go around.

That’s especially hard on Ocean Data Systems as our USA office is located in the Boston area. We’ll keep working with Bear Republic, supporting them with Dream Report so that they can increase production and get Massachusetts back on regular distribution.

That Racer 5 IPA is great stuff!